Refurbishing Old CNC Foam Contour

Cutting Machines

Today’s foam business is much changed since even 10 years ago. A decade ago the business environment was more stable, with big accounts and large orders common place. It did make sense for companies to make investments in a new, expensive contour machine. At that time there were not many other choices, quality second hand machines were less costly but difficult to find. Our experience with second hand equipment is that quality contour cutting machines are rarely available, good equipment is an asset that companies typically hold on to. Second hand equipment that is available typically has mechanical problems, needing costly service or parts replacement. The second hand machine is typically available because the company is looking to sell it to free up cash to purchase a new machine. Not many companies, if any, were offering to refurbish old machines.

Today the foam business is more volatile and unpredictable, with fewer accounts and smaller orders. Now it does make sense to think of refurbishing your machine or purchasing a refurbished CNC machine.

We are experts in refurbishing CNC machines. Let us complete a make-over of your CNC machine and we will return to you a CNC machine that is "almost" new, improved, and ready to provide years of reliable service much cheaper than the cost of a new CNC machine.

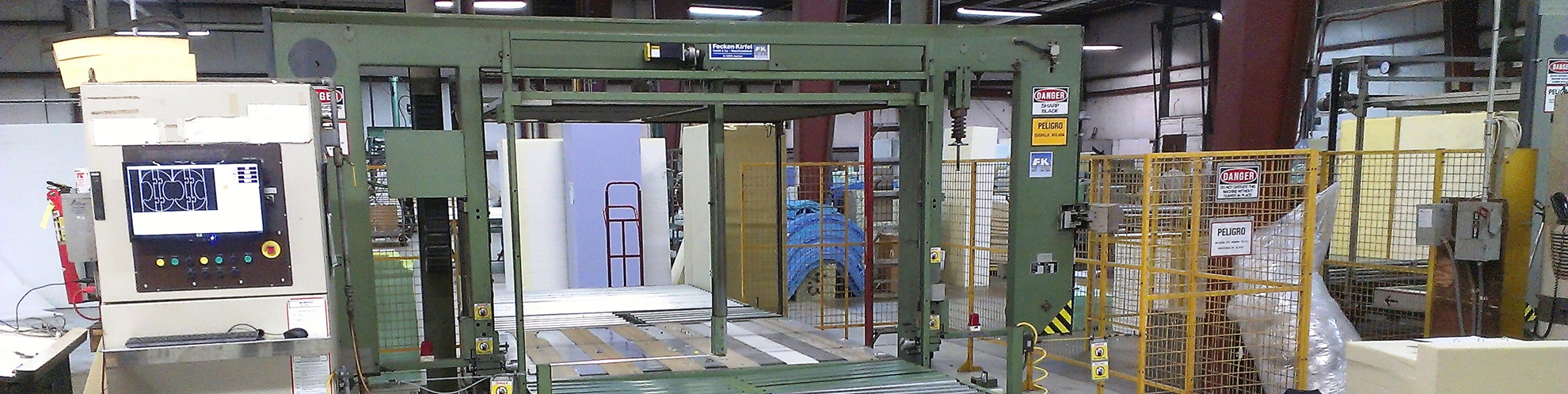

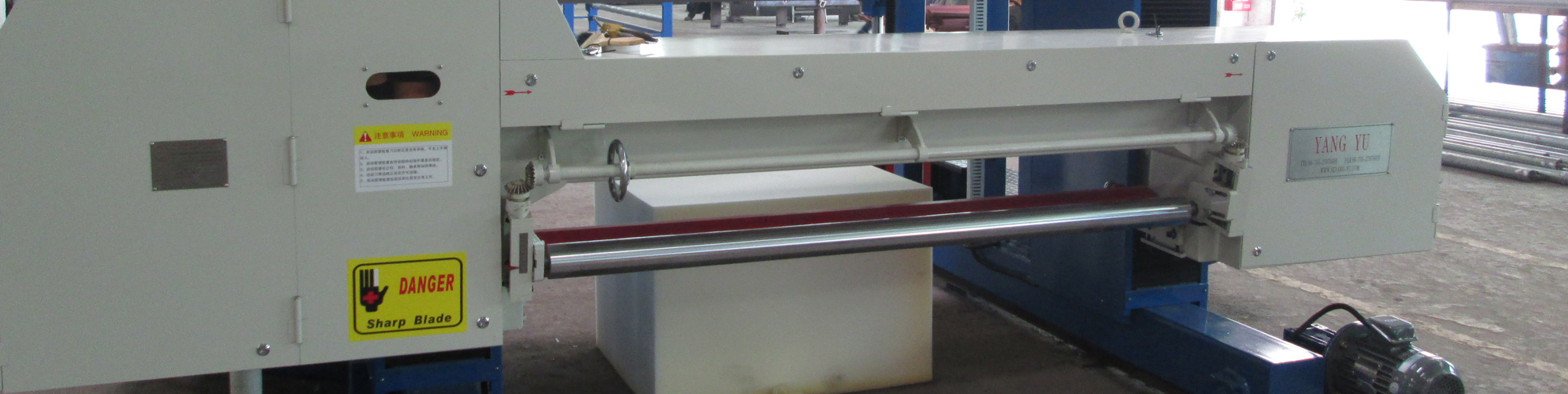

- Refurbishing process of a CNC contour machine consists of the following:

- * Complete disassembly of the machine.

- * Replacement of all worn out parts with new ones.

- * Mechanical upgrades or improvements if needed.

- * Complete new paint job.

- * All new electrical wires.

- * All new CNC controller

- * New PC based Control computer running on Windows platform that can be easily networked and remotely access and troubleshoot if needed.

- * New AC Servo amplifiers, motors and cables.

- * All programming and nesting software is included (more information).

We have a great number of refurbished machines in operation today all over the country, constantly improving the technology.

The refurbishing process practically gives the machine a new life, with modern technology that is not proprietary. It is open architecture and can be easily integrated with other software packages as they become available or upgraded in the future. It gives the machine new machine reliability for a much lower price that even second hand machines.